INDUSTRIES SERVED

Let us analyze your toughest screening challenges

CRUSHED STONE

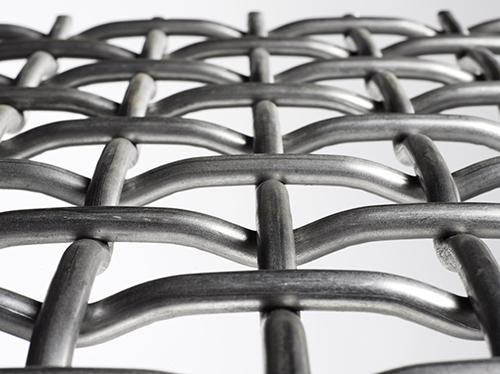

This part of the aggregate sector is, by far, where we have our most impact as a wire cloth manufacturer and for good reason. Our sales team, and the established dealer chain, works alongside America’s leading producers to provide screening solutions to increase the productivity of their operations. As first class wire cloth experts, we do not sit by idly and throw random ideas at a problem. Instead, we take the time to find a solution for your crushed stone operation.

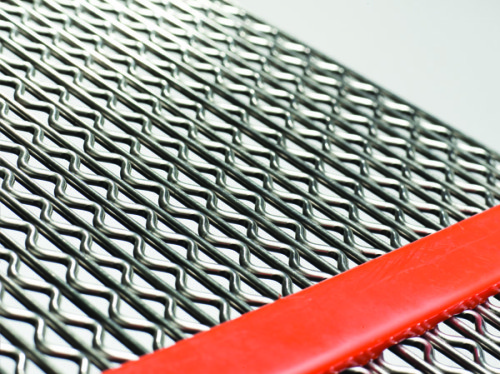

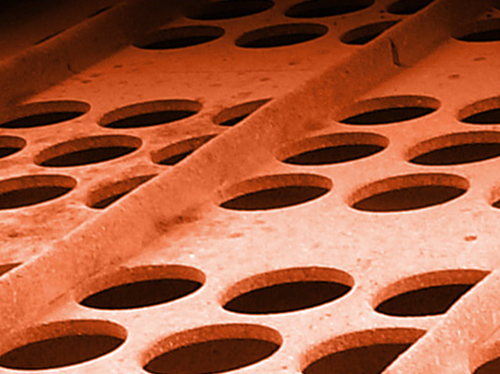

It does not matter what the application is, there is a screen media for any type of stone seen here in North America. In limestone areas, our non-blinding screens are second to none in their effectiveness to prevent blinding and plugging (check out our Serpa, Veno and double crimp square opening). Granite proves to be a tough application to contend with, but we have plenty of solutions that can increase wear life and decrease downtime (Smoothtop, Hi-Rise, Serpa, AR 430 Plate & McLanahan modular polyurethane). Sandstone is a brutal application where our traditional wire cloth does not hold up, so here at Hoyt, we provide modular polyurethane and Sharkskin for that environment.

If you have something different, please contact us and we can solve your issue – guaranteed.

SAND & GRAVEL

Just because most of our wire cloth goes into Crushed Stone operations, that does not mean we are inexperienced when it comes to assisting Sand and Gravel operations. With over 60 years of experience from our outside sales team and many more years with our extensive dealer chain, there is not a screening application for a Sand and Gravel plant, we have not seen. With any number of options, we can provide you with a screen media that can prevent your down time and increase your production.

Our square opening and slotted screens are second to none in their exceptional quality. If you find that wire cloth is not solving your issues, our Sharkskin screens can extend your wear life while maintaining the open area that is needed to hit production goals. Modular polyurethane, AR Plate and any of our self-cleaning screens will be able to get your production where it needs to be.

CONCRETE RECYCLING

Hoyt Wire Cloth has started to provide a large number of Concrete recycling companies – a growing industry over the last couple of decades – the tools needed to succeed. As more and more concrete needs recycled, companies are looking for high quality wire cloth to hold up to the high tonnage that is coming through their portable screening plants.

No matter the application, Hoyt Wire Cloth has the ability to provide you with what you need to get the job done. Portable crushers come in all different sizes, with “quirks”, and are taylor-made to help increase production. Our square opening will hold up in any high-volume application. If a non-blinding screen is needed, our Veno and Serpa screens will provide great solutions.

ASPHALT/RAP

Looking for a non-blinding screen to go into a hot batch asphalt plant and cannot find anything that does not have a polyurethane binding? Here at Hoyt, we can manufacture any one of our non-blinding screens (Serpa, Veno, Slotted) without polyurethane on the binding.

Our world class manufacturing facility can create any non-blinding screen with a woven binding that has been tried and true for over 30 years. This will allow you to get the same amount of “action” out of a screen and will help you to stay in spec at the same time. Do not hesitate to call one of our educated staff to assist you in this very important decision.

COAL INDUSTRIES

Hoyt has serviced the bituminous and, anthracite coal as well as the metallurgical coke industries for over fifty years. We understand the screening issues that coal producers face. Our screening products are designed to reduce both blinding and recirculating loads in screening circuits.

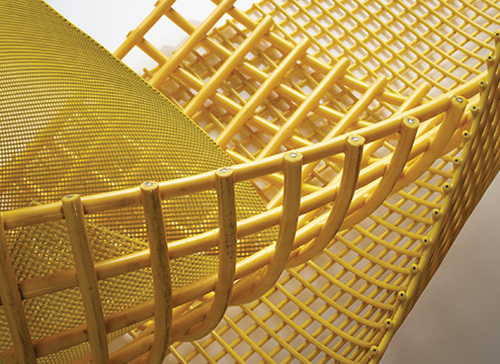

LANDSCAPING/MULCH

This is an industry that is drastically seeing the importance of having high caliber wire cloth in a trommel screen/portable screener. Most companies that fall under this category do not understand that quality wire cloth can increase their production level beyond what they originally thought possible.

HiRise is currently becoming the most popular style of wire cloth for any mulch/topsoil application. With an increase of 15% in production, and the ability to fit into any trommel screen, this product will increase profitability in this industry. Hoyt Wire Cloth can also modify any wire cloth to help in a specific application and one of our trained Sales Managers/authorized dealers can help determine the right solution.