HOYT WISDOM

Let us analyze your toughest screening challenges

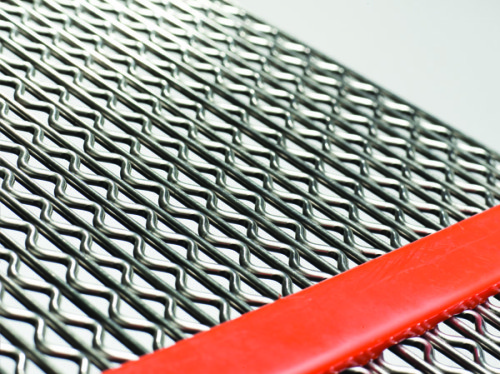

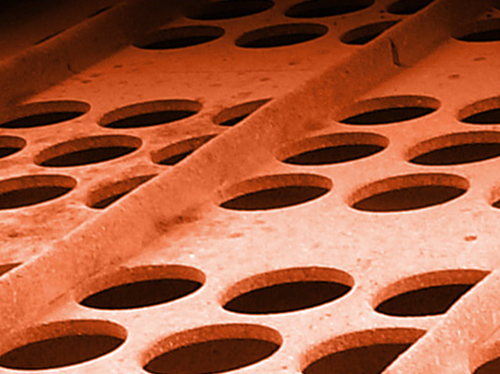

Plugging/Pegging

Plugging/Pegging This is the occurrence of near-sized material trapped in the openings, or apertures, of the screen media’s openings. This “near-sized” material attempts to pass through the openings, but because of its particular shape, this aggregate cannot freely travel over, or freely pass through, the apertures. Therefore, these aggregate particles become “wedged” in the openings and cannot be dislodged, creating the plugging or pegging conditions. Plugging or pegging can severely inhibit efficient aggregate production and, often creates a fine carry-over situation where product contamination exists; e.g., the fines

Blinding

Blinding Deck blinding is a real challenge for many aggregate operations. Soft, powdery limestone is notorious for bad blinding, but this problem can occur in almost any type of aggregate. Dust-sized particles often deposit themselves on flat surfaces inside a shaker, including the tops of the screening wires. Add a little moisture and the deposits become like hard cement. Please refer to the diagram at right. The blinding process usually starts with a clean wire (#1), and then the powdery deposits stick to the wire (#2). This

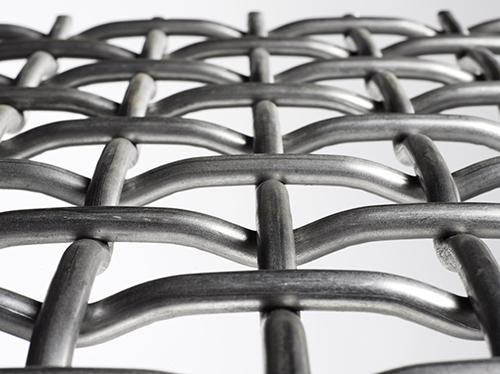

Throughput & Screening Efficiency

Throughput & Screening Efficiency These two terms cannot be considered without regard to the screen media’s wear-life. Depending on the particular screening media in use, there is sometimes a fine line between efficiency and wear-life. The Vibrating Screen Manufacturers Association (VSMA) or the manufacturer of your vibrating screen can accurately determine the screening capacity needed on each deck for your aggregate separation requirements. These screening efficiency calculations involve aspects such as tons per hour, top size feed, open area of the screen media, and the inclination of the

The Impact of “Impact” Wear

The Impact of "Impact" Wear Transporting, crushing, conveying and the screening aspects of all aggregate processing facilities deal with localized and, in many cases, severe wear areas. Areas of aggregate impact upon processing components can create unusually rapid wear where aggregate is transferred from one point to another in the processing flow. Depending upon the “transfer mode” and the impact media in use, the “impact of impact” can be minimized. Other than aggregate conveying, two specific “modes” of aggregate transfer are involved in almost all aggregate processing

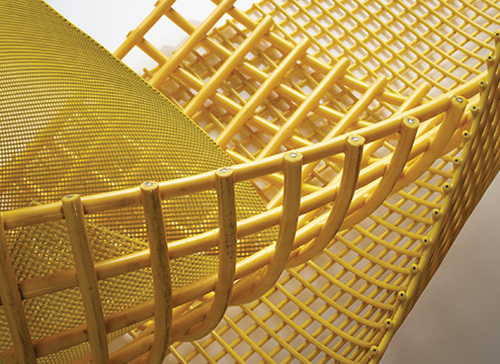

Installation Procedures & Tips

Installation Procedures & Tips Proper Installation is the key to performance and longevity. We’ve compiled a few procedures and tips to help ensure proper installation and proper performance going forward. Be sure that the screen media’s panel dimensions are correct for your vibrating screen. Panels that are too narrow or too wide cannot be properly tensioned and will self-destruct. Normally, the outside hook dimension for most screening media is approximately 1-1/2″ narrower than the “distance between the side plates” of the vibrating screen. This allows proper engagement of