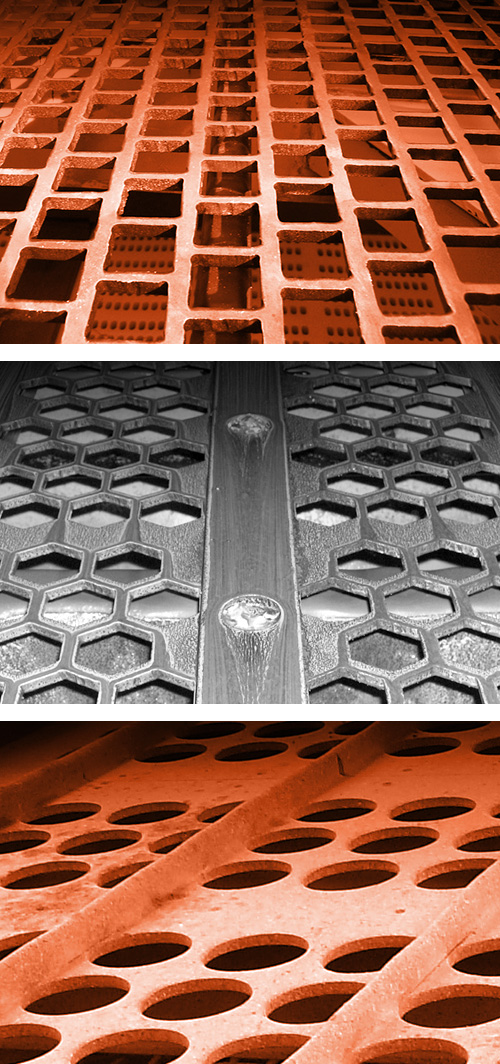

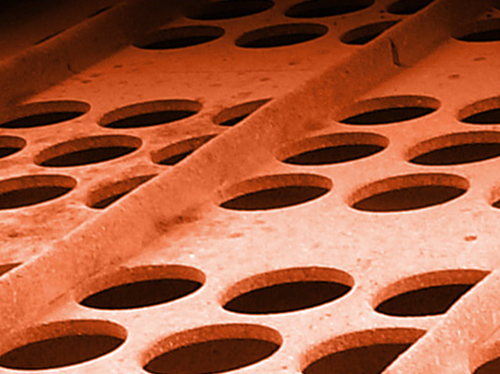

PERFORATED PLATE

162 Brinell Plate

This is an “as rolled” (not heat treated) plate material that has a hardness of 162 on the Brinell hardness scale. It has a hardness of 85 on the Rockwell “B” scale and, therefore, is sometimes known as 85b plate. This material has a low initial cost and is best suited for the screening of relatively non-abrasive materials such as limestone.

235 Brinell Plate

A relative newcomer to perforated plate materials, 235 Brinell material is also “as rolled.” A somewhat “beefier” chemistry and different mill rolling techniques give this material greater abrasion resistance than standard 162 Brinell materials. Somewhat more costly, it can be effective when used in more abrasive applications such as high-silica sandstone and lower-abrasion granite.

280 Brinell Plate

This quench and tempered (heat treated) material has been an industry “workhorse” for many years. While the heat-treating process adds more expense to the product, it also allows the plate to last a long time in very abrasive environments such as crushed granite and granite-based sand and gravel. For the ultimate in cost-effective perforated plate screening in any material, however, Hoyt recommends JADCO QT-PLUS™ (see below).

JADCO QT-PLUS™

Hoyt Wire Cloth is an authorized distributor for JADCO QT-PLUS™ perforated plates. QT-PLUS is the ideal choice for extreme abrasion and/or impact. In addition to outstanding abrasion resistance, JADCO’s proprietary chemistry offers excellent weldability and amazing ductility. The Brinell hardness of QT-PLUS™ is 461 to 537 in thicknesses up to 1″. It is not uncommon for QT-PLUS™ to outwear 162 Brinell plate by a factor of 10:1 and standard AR400 by 2:1. QT-PLUS™ is also available in custom-cut chute liners, feed box liners, discharge lip liners, crusher feed liners and cutting edges. Your Hoyt sales representative can take the proper measurements and provide cut-to-fit custom-wear items fabricated from QT-PLUS™.