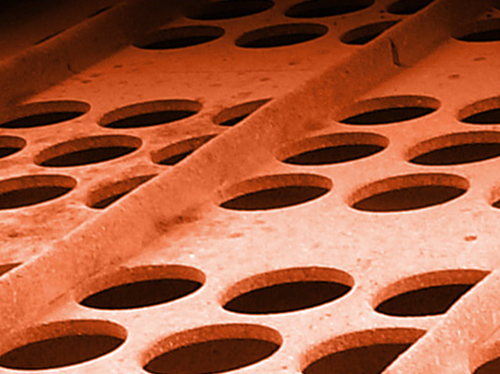

WOVEN WIRE SCREENS

Square Openings

(Opening sizes: 3/32″ – 8″)

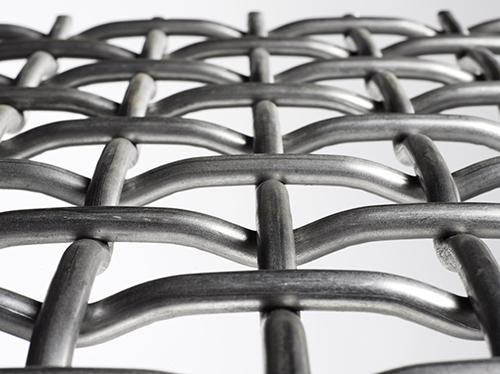

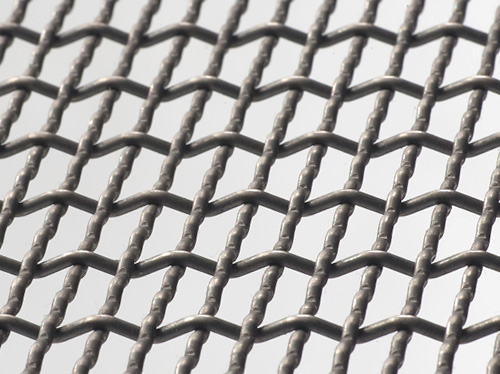

Square openings are by far the most commonly used opening shape in the aggregate industry. Specific aggregate material gradations are normally produced through, and tested by, square opening screens. Hoyt Wire Cloth’s manufacturing tolerances for square openings are more rigid than the ASTM standard for woven screens. These “tighter” manufacturing opening tolerances offer the benefits of longer screen cloth wear-life and production of accurately sized aggregate material. Due to the abrasive action of the aggregate upon the screen openings, these openings eventually become larger, passing larger material. Once the opening size becomes too large, the screen panel must be replaced. However, due to tighter tolerances, longer effective wear-life and production is realized with Hoyt’s woven wire screens.

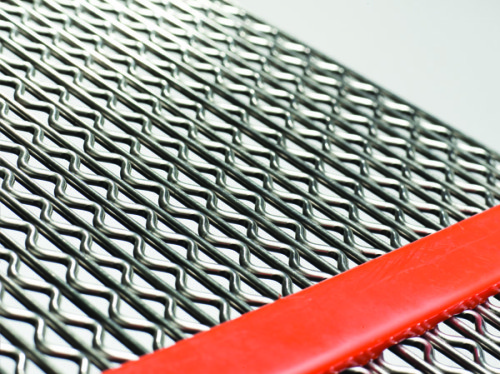

Oblong Openings

(Opening sizes: 1/16″ – 6″)

Oblong-shaped openings offer two distinct advantages over square openings: more open area/screening efficiency and greater wear-life, depending on the specific screening application. Additionally, oblong openings can be used where square opening screen cloth is plugging and/or not suitable due to wear-life and production concerns.

Hoyt manufactures oblong openings with oversized “fill wires” that firmly lock all wires into place, preventing looseness and extending wear. Oblong openings can be designed to match the conditions and support bars on each particular vibrating screen and are available with material flow, or across material flow, depending on the vibrating screen in use.

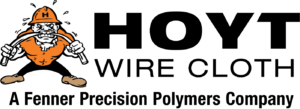

Longslot Smoothtop Openings

(Opening sizes: 5/64″ – 6″)

Hoyt’s unique “press crimping operation” produces Longslot opening panels that are tightly woven with accurately sized openings. Longslot openings are especially suitable for use when maximum open area and screening efficiency is required in the removal of fine material, from the over sized. Again, larger-diameter “fill wires” are used to firmly lock all wires into place, preventing looseness and extending screen panel wear-life. The Smoothtop construction exposes more wire mass to the aggregate flow on an evenly wearing surface. No high points (knuckles) are higher than the wearing surface. These “high points” quickly abrade away and shorten the wear-life of the screen cloth panels. Hoyt positions all “high points/knuckles” on the underside of the screen panels, thereby maximizing wear.

Smoothtop Twin™

(Opening sizes: 5/64″ – 6″)

Hoyt’s unique “press crimping operation” produces Longslot opening panels that are tightly woven with accurately sized openings. Longslot openings are especially suitable for use when maximum open area and screening efficiency is required in the removal of fine material, from the over sized. Again, larger-diameter “fill wires” are used to firmly lock all wires into place, preventing looseness and extending screen panel wear-life. The Smoothtop construction exposes more wire mass to the aggregate flow on an evenly wearing surface. No high points (knuckles) are higher than the wearing surface. These “high points” quickly abrade away and shorten the wear-life of the screen cloth panels. Hoyt positions all “high points/knuckles” on the underside of the screen panels, thereby maximizing wear.