SELF-CLEANING SCREENS

Let us analyze your toughest screening challenges

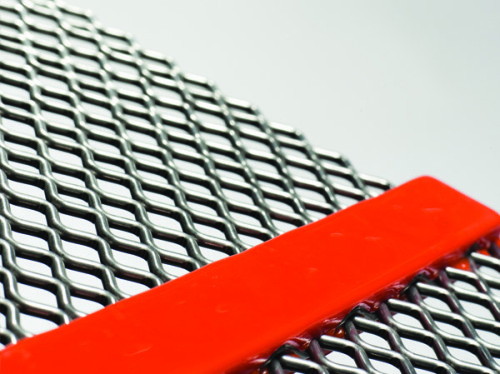

Hoyt Serpa™ Flat Fill Screen

(Opening sizes: 1/8” to 1 ”)

Hoyt’s Serpa Flat Fill is a patented self-cleaning screen that utilizes flattened fill wires to increase wear life and eliminate the need for polyurethane bindings. Serpa Flat Fill is engineered to increase open area and boost production of accurately sized material while eliminating the blinding and plugging that occurs during screening of aggregates. Best of all it offers a real cost advantage over screens with traditional polyurethane bindings, with comparable wear characteristics.

It is ideal for mid-range to light-range screening applications, allowing you to meet American Association of State Highway and Transportation Officials (AASHTO) specifications for critical 1/8” to 1 ” openings. It also meets Superior Performing Asphalt Pavements Super pave material-sizing requirements.

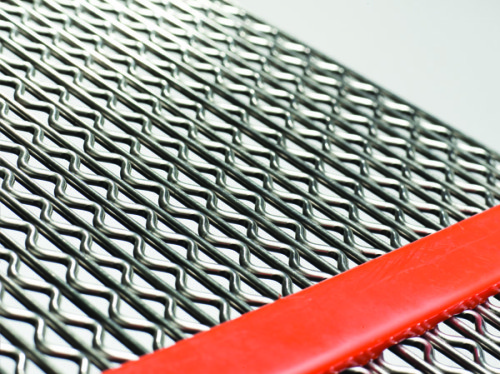

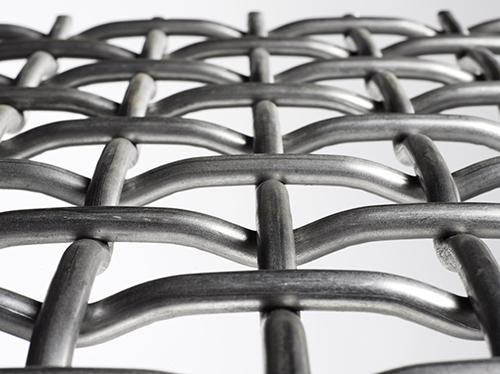

Hoyt Veno™ Screen

(Opening sizes: 5/64″ – 7/8″)

This particular non-blinding screening surface was the original Hoyt non-blinding screen. The Veno™ Screen was initially designed in Dusseldorf, Germany, over 75 years ago. Lumsden Corporation/Hoyt Wire Cloth, through the vision of founder Alexander D. Lumsden, was the first American company to introduce non-blinding woven wire screens into the United States.

The Veno™ Screen is specifically engineered and designed to alleviate blinding and plugging conditions when the use of conventional square opening wire cloth is not acceptable. The Veno™ Screen accurately controls material sizing, both through and over its screening surface, while staying clean and remaining efficient.

Veno™ works on the principle of wire movement. It is designed with alternating pre-straightened “straight wires” and alternately crimped “sizing control” wires. Both straight and crimped wires are alternately woven together with “binding wires”, which are placed directly over the longitudinal support bars (bucker-up bars) on the vibrating screen. For additional wear-life, the binding wires can be covered with abrasion-resistant polyurethane for superior wear-life. Veno™ should be considered in applications where accurately sized material is required and blinding conditions are moderate. The Veno™ Screen is ideally suited for use in Hot Mix Batch Asphalt Plants to alleviate plugging conditions. In this case, polyurethane will not be applied to the bindings.

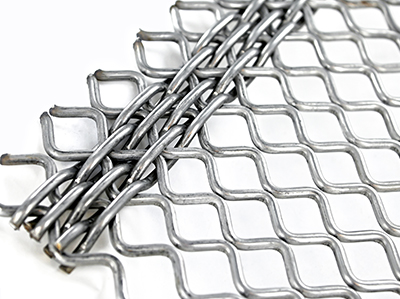

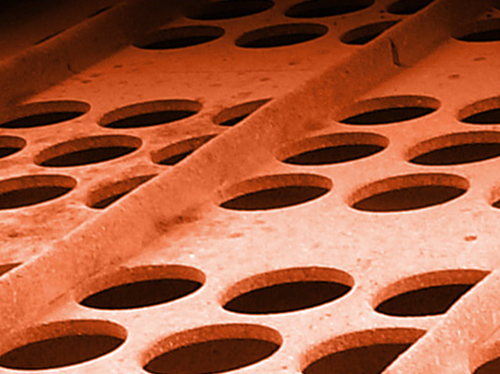

Hoyt Serpa™ Screen

(Opening sizes: 3/64″ – 1-1/2″)

Hoyt’s Serpa™ Screen is specifically designed to eliminate the blinding and plugging conditions associated with screening blind-prone and plug-prone aggregate and other difficult-to-screen material. The Serpa™ Screen is engineered with precisely crimped wires and woven into “diamond” shaped openings. Serpa™ offers more effective open area due to the lack of straight wires that are present in the Veno™ Harp Screen. Ideal applications of the Serpa™ Screen are in mid-range to light-range screening applications. Serpa™ effectively controls the material sizing of AASHTO specifications, which is most important for 1/8″ to 3/4″ openings, while also increasing production of this accurately sized material. Despite the ever-stringent material-sizing requirements dictated by “Super-Pave,” the Hoyt Serpa™ Screen carefully meets this screening efficiency and sizing challenge.

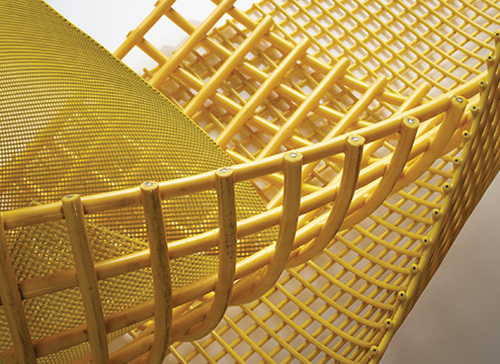

Hoyt Serpa XLT™ Screen

(Opening Sizes: 5/32″ – 1-5/8″)

This newly developed, high-efficiency screen combines the screening efficiency of the Serpa™ Screen, although it performs better when screening heavy loads. The Serpa XLT™ utilizes round wire that is compressed and formed into an “oblong” configuration design. These crimped “oblong” wires are then woven to create the Serpa XLT™ Screen. Serpa XLT™ is ideally suited in applications where a majority of the material to be processed is oversized, e.g., removal of the fines from the course material. Here, the Serpa XLT™ Screen is engineered to withstand heavier deck loads while eliminating plugging and blinding conditions.

Notice that blinding is only over the support bars, not in the screening area. Due to its increased height of round-wire compression into an oblong-shaped wire, Serpa XLT™ is an ideal choice where abrasive material is screened. This compression and expansion offers significantly greater throughput and wear-life. In fact, the term “XLT” stands for Extra Life & Throughput.

Hoyt V-1™ Screen

(Opening sizes: 1/16″ – 1″)

The Hoyt V-1™ Screen is perhaps the highest production screen available when “rough” material sizing is required or in applications where fine removal is needed. V-1™ is manufactured with only “pre-straightened” wires, positioned parallel. The Hoyt V-1™ Screen is an ideal choice for screening applications where harp screens are used. V-1™ Screens are woven together via binding wires, as previously mentioned. Because pre-straightened wires are used, uniform tensioning occurs on ALL the wires, and, subsequently, premature wire breakage and screen failure is eliminated. Additionally, larger wire diameters can be used in the manufacturing process of the Hoyt V-1™ Screen. Larger wire diameters naturally increase wear-life without significantly sacrificing “effective” open area and screening efficiency. Polyurethane bindings also are available for extended wear.

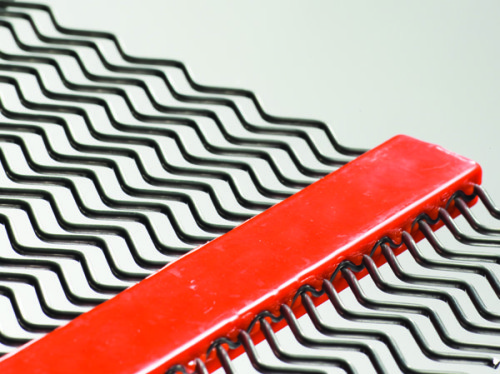

Hoyt H-Wave™ Screen

(Opening sizes: 5/64″ – 3/4″)

This highly efficient, non-blinding screen was recently developed to eliminate severe blinding and to offer additional sizing control in difficult to screening applications. The Hoyt H-Wave™ Screen is engineered and manufactured in a uniformly crimped “Herringbone Design.” The crimped wires, positioned horizontally and parallel, offer better sizing control than the V-1™ Screen by eliminating more Flats and Elongates.

The H-Wave™ Screen performs well in more extreme blinding situations. The Hoyt H-Wave™ Screen is an excellent choice in extreme blinding screening situations where material sizing is important, though not critical. The H-Wave™ Screen is proven highly effective in RAP plant asphalt screening applications and with other similar but difficult aggregate separation requirements.