SCREENING ACCESSORIES

Let us analyze your toughest screening challenges

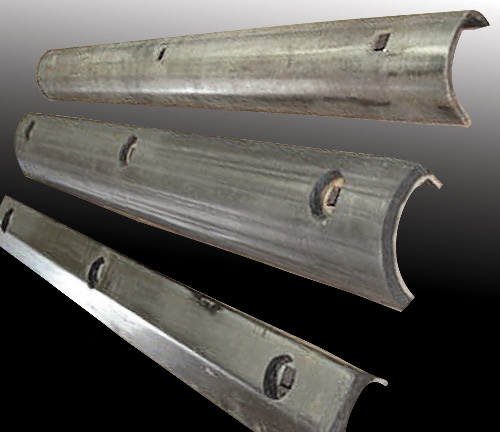

Channel Rubber/Bucker-Up Rubber

(Opening sizes: 3/32″ – 8″)

Channel rubber or bucker-up rubber, as it is frequently called, is the single most important factor in preventing “metal to metal contact” when wire cloth or other tensioned screen media is used on vibrating screens. Channel rubber or bucker-up rubber acts as an “effective cushion” to prevent these screening surfaces from coming into direct contact with the steel supporting bars. Without channel rubber, “surface to surface contact” will occur, and the resulting destruction of the screening media (from the underside) is imminent.

Hoyt’s channel rubber is specifically designed to prevent this occurrence. Not only does Hoyt’s channel rubber prevent “surface to surface contact” but, more importantly, Hoyt’s high-quality channel rubber exerts upward pressure on the tensioned screening surface. This constant and upward pressure prevents unexpected wear (from the underside), saving you the cost of additional replacement panels, labor and downtime. Channel rubber is inexpensive when compared to the price of replacement screen panels, labor, and, most importantly, unexplained downtime.

Hoyt Stocks the Following Channel Rubber Sizes for Immediate Shipment:

1/4″ Channel – 75 ft. per carton

3/8″ Channel – 75 ft. per carton

1/2″ Channel – 75 ft. per carton

3/4″ Channel – 50 ft. per carton

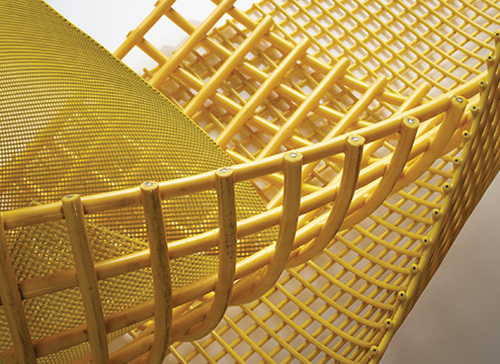

Polyurethane Channel Strips

Hoyt stocks long-wearing polyurethane support bar strips for “severe and unique screening applications.” Polyurethane channel strips offer much greater wear-life and extra-wide support for special screening surfaces and screening applications. Please contact us for more information.

Installation Tip: When replacing channel rubber, please be sure that all support bars are covered with the same brand. It is also important that new channel rubber be installed on all support bars. Using different types of channel rubber or only replacing the worn channel rubber will prevent even tensioning, due to different heights, and could lead to premature screen media breakage.

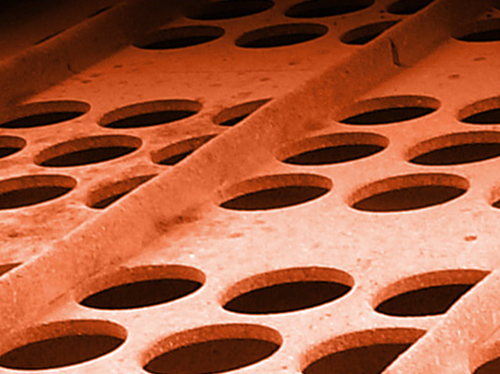

Skirtboard Rubber

Hoyt can supply skirtboard rubber for almost any application. The rubber can be punched or slotted if desired. Your Hoyt representative will be glad to examine your application and take the proper measurements for a perfect fit. Shipment of stock items can be made immediately.

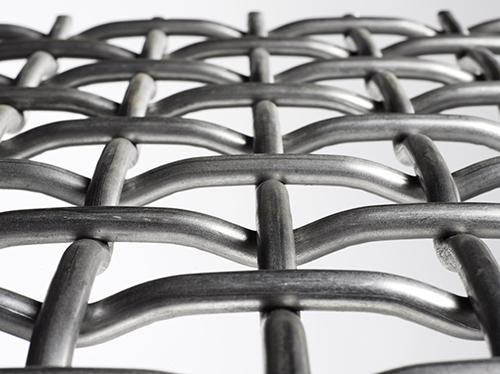

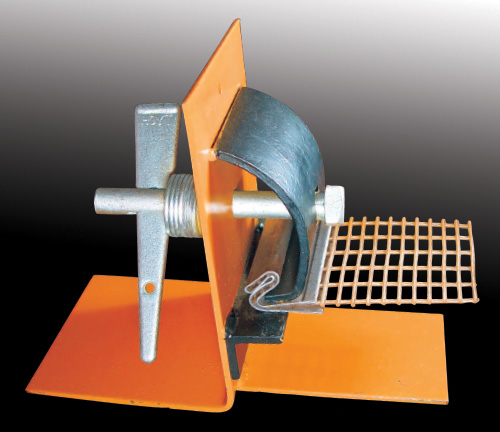

Tension Wedges & Components

The Hoyt tension wedge assembly, consisting of a slotted bolt, tension wedge, spherical washer and the flat hardened washer, greatly speeds installation of all tensioned screen media. Just a couple of hammer blows either tightens or loosens the screening panels, saving labor and downtime. Stripped threads on tensioning bolts, pneumatic wrenches, and cutting torches are eliminated with the use of Hoyt’s Tension Wedge Assemblies. A simple hammer is the only tool required to adequately tension most screen media. Tension wedges and bolts are made of forged alloy steel for superior abrasion resistance, and all tension wedge components are in stock for immediate delivery. Both 3/4″ diameter long bolts (6-5/16″), and 3/4″ diameter short bolts (4-3/4″) are available.

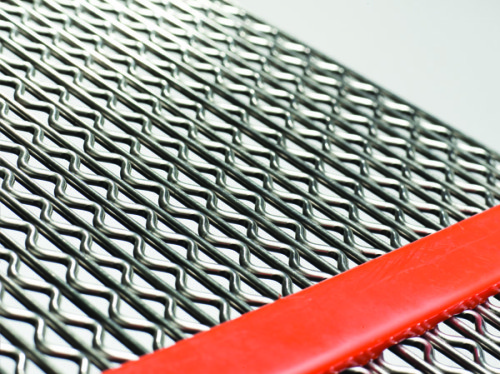

Tension Rails & Tension Bolts

These two high-wear, replaceable items are used in conjunction to properly tension screen cloth, perforated plate, and rubber screen panels, along with tensioned polyurethane screening media. Tension rails and the tension bolts are commonly used on side-tensioned vibrating screens to firmly tension and attach these various screening media onto the vibrating screen deck. Based on the particular “tensioning design” of each vibrating screen, there are several important factors to consider that will eliminate possible screen media breakage and maximize wear-life.

Hoyt Wire Cloth stocks several different types of tension rails, each designed for a specific vibrating screen. Rubber covered tension rails are also available for highly abrasive screening applications. We also stock grade #5 and grade #8 tension bolts in various lengths for immediate shipment.